Excavation Contractors Pasco

Find the best Land Excavation in Pasco

Receive up to 3 Excavation Contractors quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best service.

Service Needed

City or Town

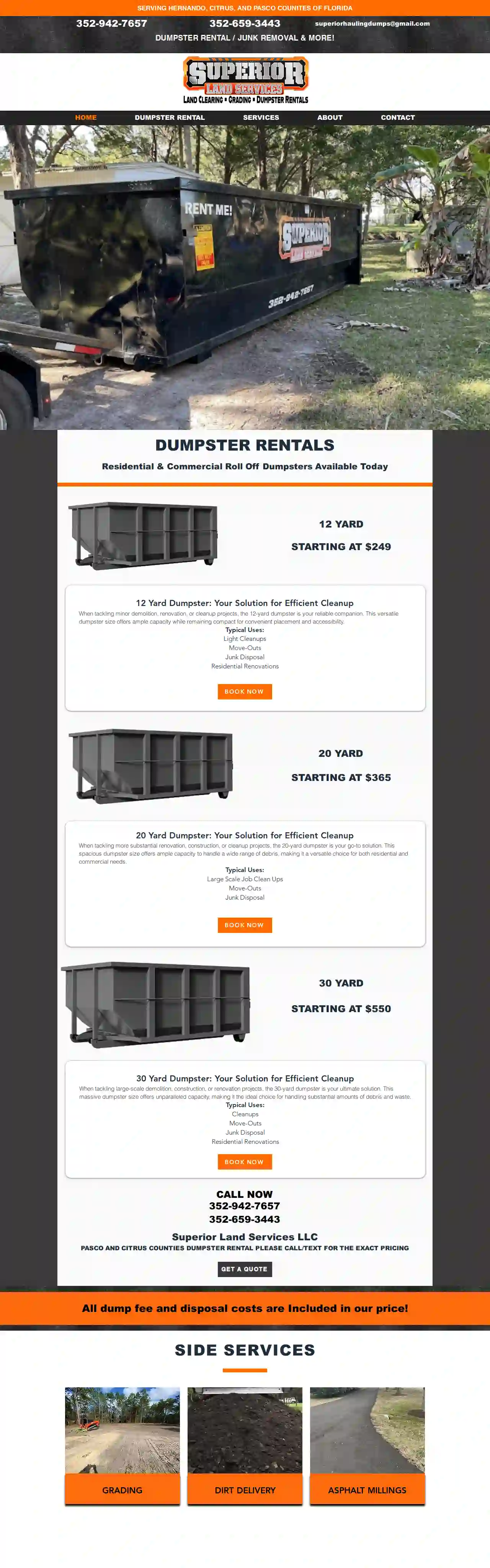

Superior Land Services LLC

4.539 reviewsPasco, US- Services

- Why Us?

Get Quote- Di

Dirt Kings LLC

52 reviewsPasco, US- Services

- Why Us?

- Gallery

Get Quote - As

Ashton Excavating, INC

51 reviewsPasco, US- Services

- Why Us?

Get Quote - PA

PASCO EXCAVATION, LLC.

Pasco, US- Services

- Why Us?

Get Quote

Menendez Excavation LLC

11 reviewsPasco, US- Services

- Why Us?

Get Quote

Over 22,076+ Excavation Businesses registered

Our excavation companies operate in Pasco & beyond!

ExcavationHQ has curated and vetted Top Excavation Businesses in Pasco. Find a top & reliable pro today.

Frequently Asked Questions About Excavation Contractors

Find answers to common questions about excavation contractors and hiring excavation professionals in the USA.

- Clearly Define the Scope: Outline the project's goals, including the excavation area, depth, grade, and intended use.

- Obtain Necessary Permits: Research and acquire any required permits from your local authorities.

- Mark Utility Lines: Contact your utility companies to locate and mark underground utilities to prevent damage.

- Communicate with Neighbors: Inform your neighbors about the project's timeline and potential noise or disruptions.

- Prepare the Site: Clear any obstacles, such as vegetation, furniture, or structures, from the excavation area.

- Discuss Safety Protocols: Review safety procedures with the contractor to ensure a safe work environment.

- Hauling to Designated Disposal Sites: Transporting excavated material to approved landfills or recycling centers.

- Recycling or Reuse: If suitable, some excavated soil might be recycled for other projects or reused on-site for landscaping or backfilling.

- Complying with Regulations: Adhering to local and environmental regulations for soil disposal to prevent contamination or illegal dumping.

- Trench Collapses: Unstable trench walls can cave in, posing a severe risk to workers. Proper shoring and sloping are crucial safety measures.

- Utility Damage: Striking underground utilities (gas, water, electric) can cause leaks, explosions, or electrocution. Accurate utility locates and careful digging are essential.

- Falling Objects: Materials or equipment falling into excavations can injure workers. Securing work areas and using appropriate safety gear is vital.

- Equipment Accidents: Operating heavy machinery involves risks of rollovers, collisions, or mechanical failures. Trained operators and proper equipment maintenance are critical.

- Environmental Hazards: Excavated soil might contain hazardous materials (asbestos, lead). Proper testing and disposal procedures are necessary.

- Excavators: Versatile machines with a bucket, arm, and rotating cab for digging, lifting, and moving earth.

- Backhoes: Similar to excavators but with a digging bucket on the back and a loader bucket on the front, ideal for trenching and smaller excavations.

- Bulldozers: Powerful machines with a large blade for pushing earth, clearing land, and leveling surfaces.

- Skid Steers: Compact and maneuverable loaders with various attachments (buckets, forks) for digging, loading, and grading in tight spaces.

- Trenchers: Specialized machines for digging narrow trenches for utilities.

- Dump Trucks: Vehicles for hauling excavated material to disposal sites.

What should I do before excavation starts?

Prior to the start of excavation, take these essential steps:

How do you handle soil disposal after excavation?

Responsible soil disposal after excavation is essential. Excavation contractors typically handle it by:

What are the risks associated with excavation?

Excavation, while essential for many projects, involves inherent risks, including:

What equipment is used for excavation?

Excavation projects employ various heavy equipment, chosen based on the job's scale and complexity. Common equipment includes:

What should I do before excavation starts?

Prior to the start of excavation, take these essential steps:

- Clearly Define the Scope: Outline the project's goals, including the excavation area, depth, grade, and intended use.

- Obtain Necessary Permits: Research and acquire any required permits from your local authorities.

- Mark Utility Lines: Contact your utility companies to locate and mark underground utilities to prevent damage.

- Communicate with Neighbors: Inform your neighbors about the project's timeline and potential noise or disruptions.

- Prepare the Site: Clear any obstacles, such as vegetation, furniture, or structures, from the excavation area.

- Discuss Safety Protocols: Review safety procedures with the contractor to ensure a safe work environment.

How do you handle soil disposal after excavation?

Responsible soil disposal after excavation is essential. Excavation contractors typically handle it by:

- Hauling to Designated Disposal Sites: Transporting excavated material to approved landfills or recycling centers.

- Recycling or Reuse: If suitable, some excavated soil might be recycled for other projects or reused on-site for landscaping or backfilling.

- Complying with Regulations: Adhering to local and environmental regulations for soil disposal to prevent contamination or illegal dumping.

What are the risks associated with excavation?

Excavation, while essential for many projects, involves inherent risks, including:

- Trench Collapses: Unstable trench walls can cave in, posing a severe risk to workers. Proper shoring and sloping are crucial safety measures.

- Utility Damage: Striking underground utilities (gas, water, electric) can cause leaks, explosions, or electrocution. Accurate utility locates and careful digging are essential.

- Falling Objects: Materials or equipment falling into excavations can injure workers. Securing work areas and using appropriate safety gear is vital.

- Equipment Accidents: Operating heavy machinery involves risks of rollovers, collisions, or mechanical failures. Trained operators and proper equipment maintenance are critical.

- Environmental Hazards: Excavated soil might contain hazardous materials (asbestos, lead). Proper testing and disposal procedures are necessary.

What equipment is used for excavation?

Excavation projects employ various heavy equipment, chosen based on the job's scale and complexity. Common equipment includes:

- Excavators: Versatile machines with a bucket, arm, and rotating cab for digging, lifting, and moving earth.

- Backhoes: Similar to excavators but with a digging bucket on the back and a loader bucket on the front, ideal for trenching and smaller excavations.

- Bulldozers: Powerful machines with a large blade for pushing earth, clearing land, and leveling surfaces.

- Skid Steers: Compact and maneuverable loaders with various attachments (buckets, forks) for digging, loading, and grading in tight spaces.

- Trenchers: Specialized machines for digging narrow trenches for utilities.

- Dump Trucks: Vehicles for hauling excavated material to disposal sites.