Excavation Contractors Frederick

Top 10 Trenching Services in Frederick

Get multiple Excavation Contractors Near Me quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best deal.

Swenson Excavation

52 reviews1000 10th Ave NW, Austin, 55972, USAbout Swenson Excavation Swenson Excavation is a family-owned and operated business with over 20 years of experience in the excavation industry. We are committed to providing our clients with high-quality services at competitive prices. We specialize in a wide range of excavation services, including: Site preparation Grading Demolition Utility installation And more We are a fully licensed and insured company, and we are dedicated to providing our clients with the highest level of customer service. We are committed to safety and environmental responsibility, and we always strive to exceed our clients' expectations. Contact us today for a free estimate.

- Services

- Why Us?

- Testimonials

Get Quote

Legacy Lawn and Landscape LLC

4.36 reviews4315 Messara Lane, Pasco, WA 99301, 99301, USAbout Legacy Lawn & Landscape Legacy Lawn & Landscape was founded in 1999 by Nathan Pratt. Since then, we've achieved many milestones, gaining the knowledge and experience that has earned us a reputation as a top-quality landscaping firm. Our commitment is to build lasting relationships with our customers by exceeding their expectations and gaining their trust through exceptional performance in everything we do. We've proudly served the Tri-Cities area, including Richland, Pasco, and Kennewick. We now also offer landscaping and fencing services to Walla Walla, Yakima, and Spokane. Visit our Services page to discover how Legacy Lawn and Landscape can enhance your property!

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

GAME Inc General Contractor (Goodman & Mehlenbacher Ent Inc)

4.25 reviews2312 S Ely St, Kennewick, 99337, USGAME Inc. is a family-owned and operated business built on the mentality that our client’s success is our success. Since 1999, GAME Inc. has provided construction services to the Pacific Northwest. As a General Contractor, we offer a comprehensive range of solutions to help our clients reach their goals. We know that our client’s success is our success, and this is how we approach every project. We pride ourselves working as a team with our clients, the designers, inspectors, architects, and engineers to deliver quality projects, safely, on time and on budget. Through our years of experience, we have learned that there is great value in identifying bottlenecks and other issues as early as possible to mitigate costs and schedule impacts and we strive to deliver that value to our clients. We focus on planning and preparation early in the process to keep projects moving on schedule and on budget. GAME Inc. began in 1999, founded by long-time friends and colleagues Tim Goodman and Brent Mehlenbacher. Goodman and Mehlenbacher were experience in the industry, with Goodman having extensive experience as a Heavy Equipment Operator and Superintendent and Brent Mehlenbacher as a Heavy Equipment Mechanic. They decided to put their collective experiences and ideas together to create a business specializing in roadwork and underground utilities. It didn’t take long before the news about GAME Inc. began to spread. We quickly became known as a well-respected and highly sought-after contractor. We pride ourselves on doing the job right each and every time. Our experience, capabilities, and high-quality service continues to allow us to expand our business and relationships with developers, engineers, subcontractors, and suppliers. Our success led to us completing numerous construction projects in Washington and Oregon. Our growing team consists of highly-skilled tradesmen, mechanics, and construction professionals. Our modern fleet of equipment includes trucks, trailers, excavators, dozers, loaders, and scrapers outfitted with GPS technology which allows us to get the job done quickly, efficiently, and accurately. GAME Inc. continues to optimize by strategically investing in education, technology, systems, and methods that make us better and more efficient.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

Quality Backhoe Services, Inc

554 reviews123 Main Street, Anytown, 12345, USQuality Backhoe Services: Your Trusted Partner for Excavation and Site Preparation Quality Backhoe Services is a family-owned and operated business with over 20 years of experience in the excavation and site preparation industry. We are committed to providing our clients with the highest quality services at competitive prices. Our team of experienced operators and skilled laborers are dedicated to delivering projects on time and within budget. We take pride in our work and strive to exceed our clients' expectations. We offer a wide range of services, including: Site clearing and preparation Excavation for foundations, pools, and other structures Grading and leveling Demolition and removal Utility installation And more! We are fully insured and bonded, and we are committed to safety on every job site. We use only the latest equipment and technology to ensure that our work is done to the highest standards. We are also environmentally conscious and take steps to minimize our impact on the environment. If you are looking for a reliable and experienced excavation contractor, look no further than Quality Backhoe Services. We are dedicated to providing our clients with the best possible service and results. Contact us today for a free estimate.

- Services

- Why Us?

- Testimonials

Get Quote

Columbia Groundwork Inc Excavation

512 reviewsP.O. Box 1855, Castle Rock, 98611, USAbout Columbia Groundwork is a locally owned and operated, commercial, heavy, and residential excavating contractor. Our capabilities are easily scaled for each project; we can be as big or as little as our clients need us to be. Years of experience between both the owner and operators provide us the knowledge to complete all phases of your projects. Think of us as your contractor and project partner. Our philosophy is to not take every job that comes our way, but rather to seek out projects where our unique level of expertise and experience allow every project to come in on time and on budget. Being able to visualize grade, terrain and other construction challenges prior to actually breaking ground allows our team and our clients to grasp the scope of the project and to streamline the entire process. We feel that these systems allow us to bring a unique skill set to the table when bidding on projects as either a general contractor or a subcontractor. Columbia Groundwork is based in Longview, Washington but provides services throughout Southwest Washington. Specializing in excavation, land reclamation, erosion control and landscape construction. Columbia Groundwork’s dedication to safety, quality, knowledge and customer service allows them to manage all projects from inception to completion. Columbia Groundwork’s project management team ensures that all project solutions are implemented so the job is on time and on budget every time. Please visit our Facebook page to find the latest news and updates from us. Also see our Better Business Bureau accreditation and License Information .

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

Johnson Custom Farming and Excavating

3.73 reviews661 Newtown Rd, Walla Walla, 99362, USAbout Johnson Custom Farming & Excavating Since our founding in June 2014, Johnson Custom Farming & Excavating, LLC has operated with strong values aimed at understanding and serving our client’s needs. We offer a wide range of services, so don't hesitate to contact us to determine how we can help. We look forward to speaking with you!

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

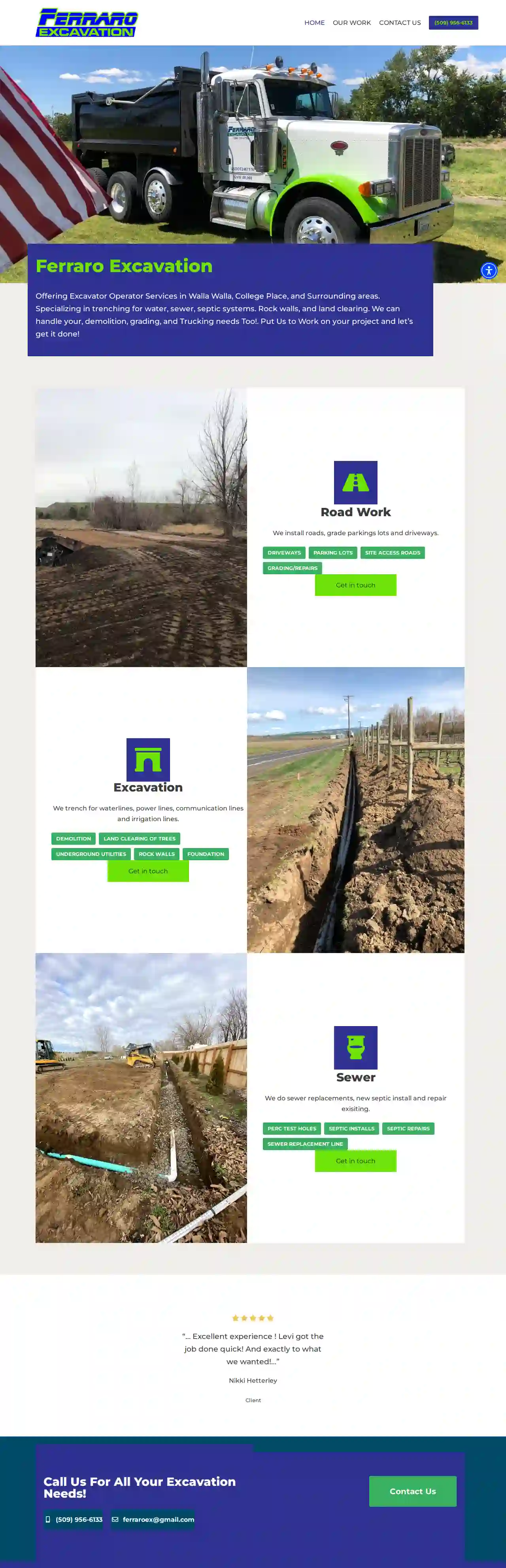

Ferraro Excavation

1Columbia, USFerraro Excavation Offering Excavator Operator Services in Walla Walla, College Place, and Surrounding areas. Specializing in trenching for water, sewer, septic systems. Rock walls, and land clearing. We can handle your, demolition, grading, and Trucking needs Too!. Put Us to Work on your project and let’s get it done!

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

Columbia land management

52 reviewsColumbia, USCommitted to Excellence Columbia Land Management is a locally owned and family operated company based in Deer Park, Wa. We have over 20 years experience in the excavation and land management trades. We are a professional, fully insured, licensed, and bonded company focused on pitting our clients first and having a strong dedication to high quality work. I always work hard to ensure my clients are completely satisfied with my work. Our wide range of services include excavation, septic installation, site prep, footings/foundations, Land clearing, utility trenching, hard scaping, roadway building and driveway installation. We use a low environmental impact approach when it comes to our excavation services and projects. Please contact us for a free consultation and let us help you create a plan that works for you!

- Services

- Why Us?

- Gallery

Get Quote

M&K Electric LLC

51 reviews1/100 Railway Parade, Perth, 6010, USAbout MKElectric MKElectric is a leading electrical contractor in Western Australia, providing a comprehensive range of services to residential, commercial, and industrial clients. We are committed to delivering high-quality workmanship, exceptional customer service, and competitive pricing. Our team of experienced and qualified electricians is dedicated to exceeding your expectations. We use the latest technology and techniques to ensure that your electrical systems are safe, reliable, and energy-efficient. Whether you need a simple light fixture installed or a complete electrical rewiring, MKElectric is the trusted partner for all your electrical needs.

- Services

- Why Us?

- Testimonials

Get Quote

Monumental Paving & Excavating, Inc.

315 reviewsBaltimore, USMonumental Paving & Excavating, Inc. COMPLETE SITE PACKAGE MANAGEMENT Monumental Paving and Excavating, Inc. is a young company - but one with deep roots in the construction industry. Founded in 1984 with a dedication to the highest quality, excellent management and to getting the job done right the first time, Monumental is a company that today sets the standards which other companies follow.

- Services

- Why Us?

- Gallery

Get Quote

Over 3,943+ Excavation Pros registered

Our excavation contractors operate in Frederick & beyond!

ExcavationHQ has curated and vetted the Best Excavation Companies in and around Frederick. Find a reliable business today.

Frequently Asked Questions About Excavation Contractors

- Determining Soil Suitability: Assessing whether the soil can support the intended structure or load.

- Recommending Foundation Types: Advising on the appropriate foundation design based on soil characteristics.

- Addressing Drainage and Erosion Issues: Providing solutions to manage water runoff and prevent erosion.

- Evaluating Slope Stability: Assessing the risk of landslides or soil movement on slopes.

- Building on challenging soil types (expansive clay, loose sand, etc.)

- Constructing large or complex structures

- Excavating near slopes or retaining walls

- Addressing drainage or erosion concerns

- Hauling to Designated Disposal Sites: Transporting excavated material to approved landfills or recycling centers.

- Recycling or Reuse: If suitable, some excavated soil might be recycled for other projects or reused on-site for landscaping or backfilling.

- Complying with Regulations: Adhering to local and environmental regulations for soil disposal to prevent contamination or illegal dumping.

- Clearly Define the Scope: Outline the project's goals, including the excavation area, depth, grade, and intended use.

- Obtain Necessary Permits: Research and acquire any required permits from your local authorities.

- Mark Utility Lines: Contact your utility companies to locate and mark underground utilities to prevent damage.

- Communicate with Neighbors: Inform your neighbors about the project's timeline and potential noise or disruptions.

- Prepare the Site: Clear any obstacles, such as vegetation, furniture, or structures, from the excavation area.

- Discuss Safety Protocols: Review safety procedures with the contractor to ensure a safe work environment.

What is a soil engineer, and do I need one?

How do you handle soil disposal after excavation?

What is the difference between cut and fill excavation?

Cut: Involves excavating soil from an area where the existing grade is higher than the desired grade.

Fill: Refers to using the excavated soil ('cut' material) to raise the grade in an area where the existing grade is lower than desired.

This method minimizes the need to import or export soil, reducing costs and environmental impact. It's commonly used for site preparation, road construction, and landscaping.

What should I do before excavation starts?

What is a soil engineer, and do I need one?

- Determining Soil Suitability: Assessing whether the soil can support the intended structure or load.

- Recommending Foundation Types: Advising on the appropriate foundation design based on soil characteristics.

- Addressing Drainage and Erosion Issues: Providing solutions to manage water runoff and prevent erosion.

- Evaluating Slope Stability: Assessing the risk of landslides or soil movement on slopes.

- Building on challenging soil types (expansive clay, loose sand, etc.)

- Constructing large or complex structures

- Excavating near slopes or retaining walls

- Addressing drainage or erosion concerns

How do you handle soil disposal after excavation?

- Hauling to Designated Disposal Sites: Transporting excavated material to approved landfills or recycling centers.

- Recycling or Reuse: If suitable, some excavated soil might be recycled for other projects or reused on-site for landscaping or backfilling.

- Complying with Regulations: Adhering to local and environmental regulations for soil disposal to prevent contamination or illegal dumping.

What is the difference between cut and fill excavation?

Cut: Involves excavating soil from an area where the existing grade is higher than the desired grade.

Fill: Refers to using the excavated soil ('cut' material) to raise the grade in an area where the existing grade is lower than desired.

This method minimizes the need to import or export soil, reducing costs and environmental impact. It's commonly used for site preparation, road construction, and landscaping.

What should I do before excavation starts?

- Clearly Define the Scope: Outline the project's goals, including the excavation area, depth, grade, and intended use.

- Obtain Necessary Permits: Research and acquire any required permits from your local authorities.

- Mark Utility Lines: Contact your utility companies to locate and mark underground utilities to prevent damage.

- Communicate with Neighbors: Inform your neighbors about the project's timeline and potential noise or disruptions.

- Prepare the Site: Clear any obstacles, such as vegetation, furniture, or structures, from the excavation area.

- Discuss Safety Protocols: Review safety procedures with the contractor to ensure a safe work environment.